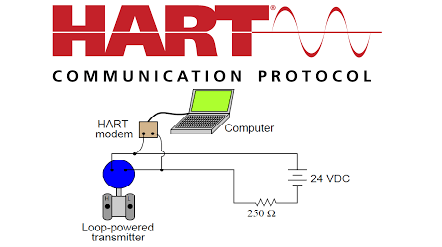

Understanding HART Protocol: Functionality, Advantages and Layers.

In this article, we will look at the complexities of the Highway Addressable Remote Transducer (HART) protocol.

Efficient communication is the foundation of the industrial world, and protocols such as HART play an important role in maintaining continuous functioning. But what exactly is HART, and how does it operate?

How the HART Protocol Works.

HART, also known as the Highway Addressable Remote Transducer, is not your typical communication channel. It works on a brilliant mechanism known as Frequency Shift Keying (FSK), which allows it to coexist with an existing analog signal, the industry-standard 4-20mA current loop.

Let's examine this digital magic's unfolding in more detail:

• Digital Riding Shotgun: HART transmits digital data by using Frequency Shift Keying (FSK). Picture a roadway with trucks acting as the analog signal, transporting essential supplies. HART smartly travels alongside these trucks, transmitting digital data at a different frequency, much like a motorbike. This makes it possible for the digital data and the analog signal to coexist uninterrupted on the same loop.

• Layers of the HART Protocol: Like an onion, the HART protocol is divided into layers, each of which builds on the one before it. These tiers specify the format, transmission, and device interpretation of data. Gaining an understanding of these layers is necessary to appreciate the intricacy and capabilities of HART.

• Master and Slave Communication: Devices function in a master-slave hierarchy inside a HART network. Multiple slave devices, such pressure or temperature transmitters, can communicate with a master device, like a control system or personal computer. The industrial process may be efficiently monitored, and the configuration of different instruments made possible by this centralized method.

Three HART Layers.

As mentioned before, the HART protocol operates in a tiered fashion, much like the computer networking industry's OSI model.

However, HART reduces this structure to only three necessary layers:

- 1. Physical Layer: This layer, which acts as the foundation, manages the actual signal transmission and reception on the 4–20 mA current loop. As was previously noted, frequency shift keying (FSK) is used by HART to modulate digital data onto the analog signal.

- 2. Data Link Layer: Data packaging happens at this layer. In order to preserve the integrity of transmitted data, it controls error detection and correction. It also manages device addressing on the network, which allows the master to speak with particular slaves.

- 3. Application Layer: This layer, which is positioned highest, defines the "language" that HART devices speak. It details the commands, formats for data, and methods of communication that the devices use. Functionalities like device configuration, diagnostics, and real-time data sharing are made possible by this layer.

Understanding the Functionality of HART Communication.

Examining how frequency shift keying (FSK) allows HART to make use of the 4–20 mA current loop:

• Digital signal transformation: is the process of converting data into frequency shifts, where high tones represent "1" and low tones represent "0." The analog current signal is superimposed with this altered signal.

• Frequency Allocation: To avoid interfering with the analog current that conveys the primary process variable, specific frequencies are selected for the digital signal. This makes it possible for both signals to function in the loop simultaneously.

HART Communication Modes.

• Multi-Drop Mode : The most popular method of HART communication is called "Multi-Drop Mode," which allows several slave devices (such temperature sensors and pressure transmitters) to connect to a single master device (like a control system or handheld communicator). In order to communicate data, the master device addresses particular slaves and starts a conversation.

• Point-to-Point Mode: With this mode, a single slave device and a single master device can communicate directly with one another. It is helpful while troubleshooting or setting up a certain device.

HART Commands.

To help with device communication, the HART protocol contains a set of common commands. Two types of commands can be distinguished from these:

• Universal Commands: These commands enable fundamental functions including reading the principal variable, modifying device configuration, and running diagnostics. They are shared by all HART devices.

• Manufacturer-Specific instructions: The creators of HART devices have the ability to add new instructions tailored to their particular instruments. These instructions might enable features like executing specific calibrations or gaining access to advanced diagnostics.

Advantages of the HART Protocol.

Envision an industrial setting where all your gadgets easily exchange data, facilitating effective administration. That is the HART protocol's genius. This is how HART enables your manufacturing processes:

1. Improved Communication: By allowing two-way communication, HART outperforms the standard 4–20 mA signal. This enables professionals to monitor real-time diagnostic data, remotely adjust devices, and spot possible problems before they become serious ones.

2. Streamlined Maintenance: Significant cost reductions are achieved by remote problem diagnosis. By using HART, technicians may identify problems without having to personally visit every device, which saves them time and money. Additionally, HART offers useful instrument health data, facilitating preventive maintenance and guaranteeing peak performance.

3. Greater Control: Operators are able to exert more control over their processes thanks to HART's real-time data sharing. Based on precise data, they may make well-informed decisions that improve plant safety, product quality, and efficiency.

4. Flexibility and Compatibility: Since HART is an industry-standard that is widely used, it can be used with a large variety of devices from different manufacturers. This adaptability lessens compatibility issues when adding new equipment and streamlines system integration.

5. Cost-Effectiveness: In the end, HART saves money by facilitating remote diagnostics, preventive maintenance, and enhanced process management. The bottom line benefits from lower maintenance costs, decreased downtime, and streamlined procedures.

Streamlining Industry: HART Protocol's Benefits.

The HART protocol is a game-changer for industrial operations, not just a means of communication. HART streamlines processes and enables effective plant management by offering a powerful and flexible communication channel. The following is how HART transforms industrial communication:

• Improved Data Exchange: HART goes beyond what the conventional 4–20 mA signal can do. It makes two-way communication possible, which permits:

o Remote Configuration: By adjusting device characteristics and settings from a centralized location, technicians can do away with the necessity of physically visiting each instrument.

o Real-Time Diagnostics: HART offers insightful diagnostic information on the condition of linked devices. This makes it possible to proactively identify possible problems before they develop into more significant ones.

o Advanced Process Monitoring: Operators have a better understanding of their operations thanks to the capacity to obtain real-time data from many instruments. This guarantees optimal operation and makes decision-making easier.

• Simplified Maintenance: HART's remote diagnostics features greatly simplify maintenance procedures. By identifying problems without physically visiting each device, technicians can save a significant amount of time and money. Furthermore, HART offers useful health data that makes preventive maintenance easier, reduces downtime, and guarantees peak equipment performance.

• Enhanced Process Control: Operators have more control over their processes thanks to HART's real-time data transmission. With precise and comprehensive data at their disposal, they can make well-informed choices that maximize productivity, quality of output, and overall plant safety.

• Flexibility and Interoperability: HART is an industry-standard that is widely used and guarantees interoperability with a wide range of devices made by various manufacturers. This adaptability removes compatibility issues and streamlines system integration when adding new equipment.

Unleash the Capabilities of HART with Rhosigma.

HART has many advantages but putting it into practice can be difficult. As your dependable partner for all your HART protocol needs, Rhosigma is here to help.

To help you fully utilize HART and its potential for your industrial operations, we provide a variety of services:

Design & Integration: Tailored HART network setup for seamless integration.

Device Configuration: Hassle-free management and optimization of HART devices.

Diagnostics & Troubleshooting: Swift identification and resolution of network issues.

Support & Maintenance: Ongoing upkeep to ensure peak HART system performance.

Are you prepared to fully utilize HART in your industrial setting? Get in touch with Rhosigma right now to schedule a free consultation!

We can create a solution specifically tailored to your needs and assist you in realizing the revolutionary potential of HART communication.