How Hardware Development Process Works | From Idea to Final Product

Explore key stages of hardware development & get a detailed look at the process, including design, prototyping, testing, manufacturing, & quality assurance

Are you ready to take your project off the ground?

If so, then you are in the right place. But before diving into the technical details, let's first understand why the hardware development process is important.

The hardware development process requires creativity, precision, and expertise. From the initial stage to the moment the product reaches its users, each step in the development process plays a crucial role in shaping the outcome.

This journey begins with a clear vision, transforming your ideas into tangible products through design, prototyping, manufacturing, and rigorous testing.

A structured approach can help you create reliable, efficient, and scalable solutions.

Let’s dive deeper and explore each stage of the hardware development process.

Stages of the Hardware Development Process

Idea Generation

This stage involves creating a plan to meet your desired goals. It's essential to clarify your objectives and gain a clear understanding of your final product, as well as the subsequent steps in the development process.

One of the most important tasks during this phase is creating a technical specification list, which will be crucial in the following steps. This list provides you with a bird’s-eye view of your project and serves as a guide throughout the development process.

The technical specification list typically includes:

- Your main product application where it’ll be used, how, and by whom

- The desired size of your product, whether minimum or maximum

- Battery life requirements based on the product's use cases

- Environmental considerations, such as whether it should be waterproof, weather-resistant, or fireproof

- Accuracy requirements for any features (keep in mind, higher accuracy may increase costs)

- Integration needs how the product should work with other systems

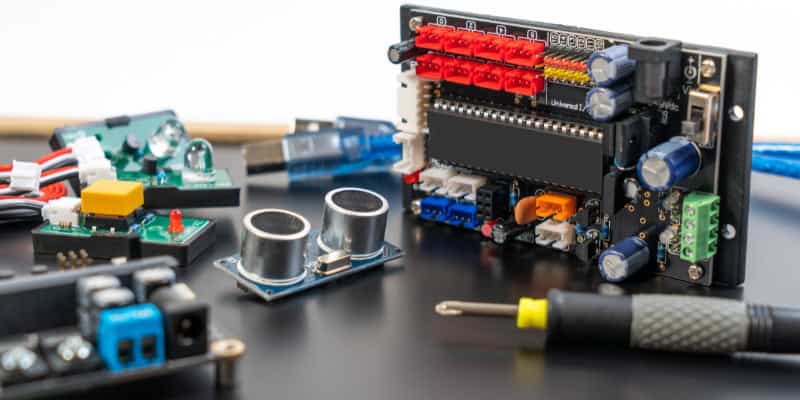

Design and Prototyping

Once you have a clear vision and technical specifications, the next step is designing and creating a prototype of your product.

In this step, your idea will take shape.

Hardware designing involves creating a detailed plan of how your product will look and work, you will focus on both the physical design(like shape, size, and materials) and technical design(how the product will function).

This is where the designer creates the design, which is often created by hand or software.

Hardware prototype development is about creating the basic version of your product and testing your ideas. It's like a "trial run" of your product. This allows you to fit together everything and identify issues before mass production.

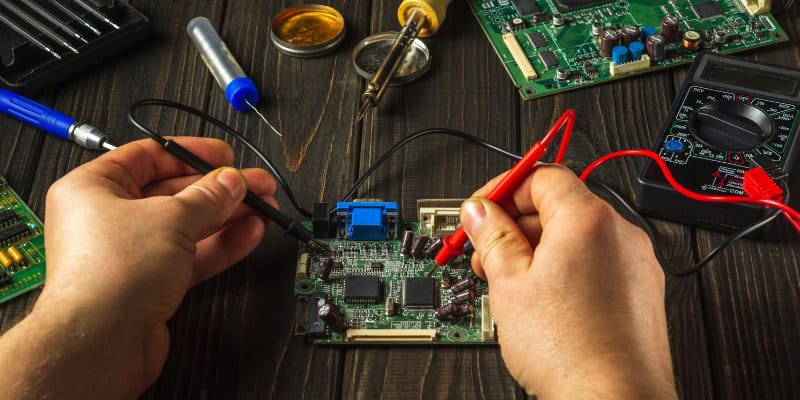

Testing and Quality Assurance

Testing and quality assurance ensure that your product works as expected, it's an important step to identify and fix issues, ensuring the final product can perform well in real-world conditions.

Different types of testing involve:

- Functional testing: This test checks if the product works as intended and evaluates the basic operations, features, and performance of the product.

- Environmental testing: it checks how the product is performing under different conditions like temperature, humidity,y and exposure to dust or water.

- Stress Testing: stress testing pushes the product to its limit and checks how the product is performing under extreme conditions. it includes overloading, using it for a long period, or exposing it to high heat or cold.

After each round of testing, the design is then refined, this process involves:

- Redesigning parts that fail under stress or environmental conditions.

- Updating the firmware or software to fix bugs or improve performance.

- Modifying materials or components to enhance durability or functionality.

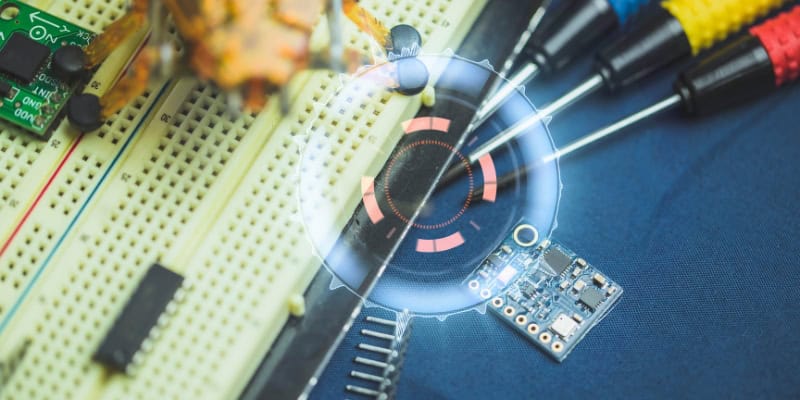

Manufacturing

Hardware Manufacturing is where your design is transformed into a physical product. it involves choosing the right manufacturing process and ensuring that the product is produced effectively and efficiently.

The manufacturing types involve:

Injection Moulding: This is used for making plastic parts.

CNC Machining: It is used for creating precise and durable parts, especially for mental or custom components.

PCB Assembly: This is where the circuit board is assembled.

Four Components of Hardware Development which are:

Enclosure: It is outer shell or casing of your product is designed to protect the internal components while making it user-friendly and visually appealing.

Circuit Board: The circuit board is the heart of your product, where all your products get connected.

Firmware: In hardware development, firmware development is an embedded software program into the product which helps to control its operation.

Software: Software development an additional software that runs on a computer or mobile device to interface with the hardware.

By carefully planning and executing the manufacturing process, you can create a reliable, scalable product ready for market launch.

Quality Assurance and certifications

Quality Assurance is also an important step in the embedded hardware development process to ensure that the final product meets all the required standards. The quality assurance process involves various processes which are:

- Inspections During Manufacturing

- Functional Testing

- Environmental and Stress Testing

- Batch Sampling

- Documentation and Reporting

Certifications and Compliance

If you want to sell your product into a global market then it must meet specific regulatory standards. These certificates ensure that your product complies with safety and environmental requirements. Some common certifications include:

CE Marking: It is required in the European Union

UL Certification: It is required for the product sold in the United States

FCC Certification: Required for electronic products sold in the United States

Launch and Deployment

This is the final stage of your product development. where the final product is ready to enter into the market.

This process involves,

Final Assembly: Here, all the components are assembled into the final product and tested to ensure everything works perfectly.

Packaging: In packaging, all the components are packed securely to avoid damage.

Distribution: The right channels are selected to distribute the final product.

User feedback: At the end, feedback is taken from the users to improve product quality and durability

Challenges in Hardware Development

This process can feel overwhelming, especially when you face common challenges like:

- Poor Initial Planning and Requirements Gathering

- Inefficient Prototyping Process

- Neglecting Design for Manufacturability (DFM)

- Underestimating Compliance and Certification Needs

- Ignoring Thermal and Power Management

- Delayed Testing and Quality Assurance

- Overlooking Scalability and Upgradability

To overcome these common challenges in hardware development, you need a clear understanding of the process or the help of experts who can guide you in the right direction.

Conclusion

Now you must have got the idea that the hardware development process is a journey that transforms innovative ideas into tangible products. In this journey every step is crucial and by following a structured approach you can ensure that your product can meet the market demand

So are you ready to bring your ideas to life, Take your next step now!

To achieve your goals, you will need the right expertise and support. Partner with Rhosigma and let's bring your vision to life, Here we provide custom hardware development solutions as per our customer's needs. contact us today, to know more.